Rubber Tires Gantry Crane

1. Introduction of tire crane products

It gets rid of the dependence of traditional cranes on tracks. It uses specially made large tires as support, can adapt to various terrains, can achieve 360° full rotation, and can shuttle freely even in very narrow spaces, showing super mobility and adaptability. In addition, compared with crawler tracks, the damage caused by tires to the ground is almost negligible. It is widely used in construction sites, ports, cargo yards, factories and other fields.

2. Product Features

1. FEM design standard: Finite element analysis is performed during the design phase to ensure design safety and structural stress safety

2. Imported brands of core components: low failure rate, long service life, and key components (such as motors and reducers) are easy to disassemble and repair. Built-in sensors can warn of potential problems in advance and reduce downtime.

3. World-leading control system: Advanced programming technology improves the reliability of crane travel and operation

4. Flexible driving: It has multiple steering modes and can be easily operated by remote control or cab. It can be transferred to different working areas by its own power or trailer to adapt to the needs of dynamic yards.

5. Space saving: The small turning radius can save the working space required by the equipment

6. Cost saving: No need to build tracks and no need to pave concrete roads, it can drive smoothly on compacted roads.

3. Product differences

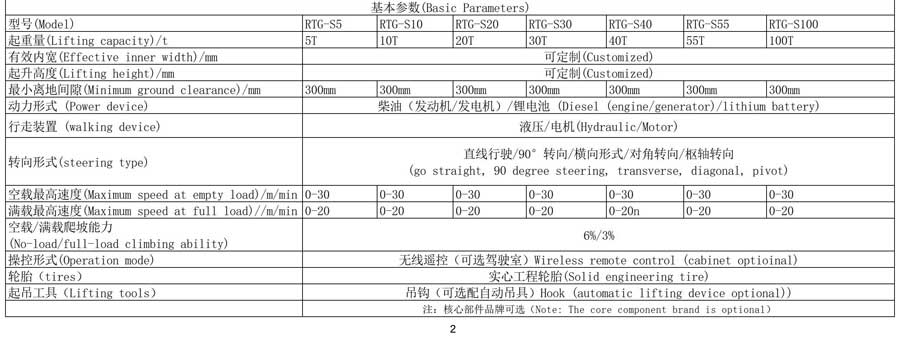

Ry cranes are available in diesel (engine, generator) and electric (lithium battery) versions. The electric version meets environmental protection requirements. The new RTG can use lithium batteries, supercapacitors or diesel-electric hybrid power to reduce fuel consumption and emissions. And the cost of use is lower. The diesel version is suitable for occasions where electricity is limited.